On the other hand, to facilitate the learning and use of various machines that possess, the client also requires man-the machine interface of various machines that has to be similar. Modular architectureĪs mentioned in the introduction, a client wishes to have machines that meet their particular needs (complex or not), in a time-limit for receipt increasingly tighter and with very demanding requirements for ease of use.

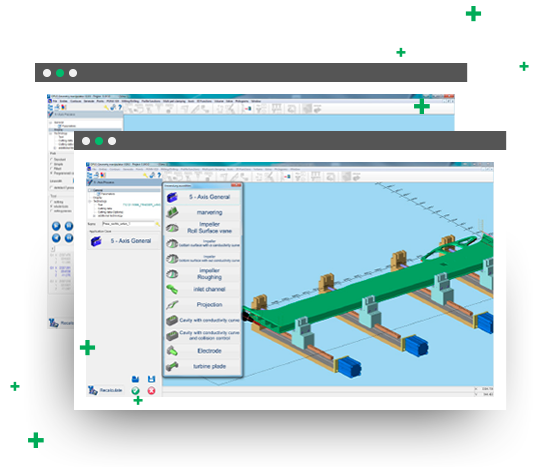

In what follows, will be used by way of example software currently in development at Danobat.

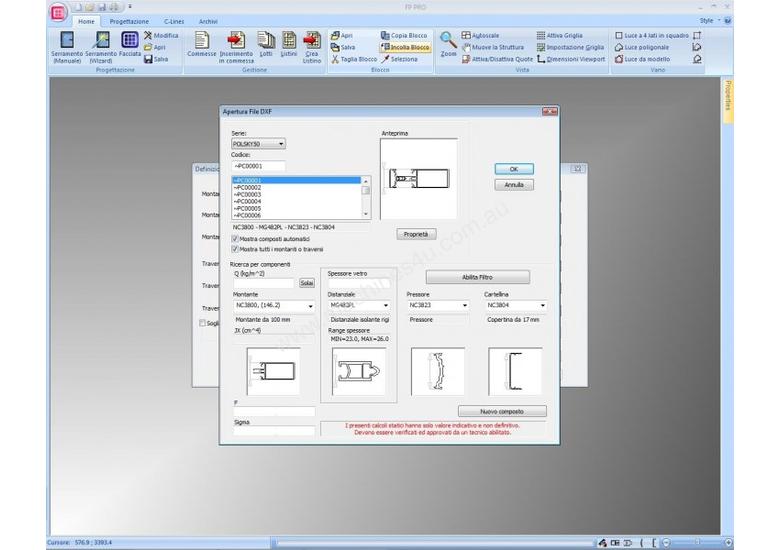

Apart from the evolution of the mechanical design, these features are the most important differentiating elements of the new generation machines, and set the trends to follow in the improvement of the relationship between the machine and the end user. This article reviews the characteristics of the integrated software in numerical control grinding machines machines currently in development. Thus, working in software developments that give the user a basic and simple environment for managing this complex process.

In the case of the grinding process, with the complexity and demand that this process requires, this milestone provides the basis on which address the development of software capable of facilitating, guiding and advising the operator to get the most out of your machine. Until the 1990s, when the first numerical controls (CNC) opened in the machine tool environment, integrate the functionality provided to the machine is limited to the possibilities of calculation, control and configuration provided by the manufacturer of the CNC/PLCleaving without any possible integration solutions and benefits software from the manufacturer.įollowing the integration of open numerical (CNC) controls, which incorporate a PC with any level of functionality it offers, provides an excellent opportunity to be able to add and incorporate into the machine operator panel all knowledge of the manufacturer, without the need for incorporating PCs or external to this hardware.

0 kommentar(er)

0 kommentar(er)